Engineered with a robust high-strength alloy frame and advanced seamless welding...

Customized Sheet Metal Products Manufacturers

Professional customized sheet metal products: precise manufacturing to meet diverse needs

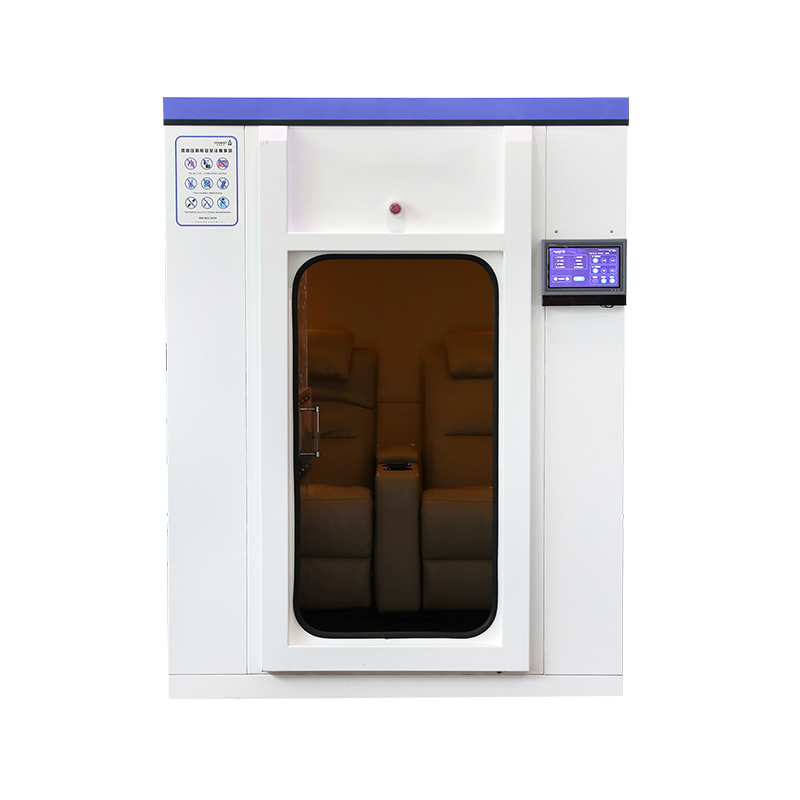

We focus on providing customers with high-quality customized sheet metal processing services, covering various products such as chassis cabinets, machine tool shells, micro-hyperbaric oxygen chambers, flower box guardrails, etc. We use advanced CNC stamping, laser cutting, bending and forming processes to ensure that the product size is accurate and the structure is stable. Different materials (such as cold-rolled steel plates, stainless steel, aluminum alloys, etc.) can be selected according to customer needs, and various treatment processes such as surface spraying, electroplating, oxidation, etc. are supported to meet the diverse requirements of corrosion resistance, wear resistance, and beauty. Strictly follow the ISO quality management system, control the entire process from design to production, and ensure that each product meets industry standards. Whether it is industrial equipment supporting or special application scenarios, we can provide flexible and efficient customized solutions to help customers improve product competitiveness.

The company has fixed assets of 140 million yuan, more than 200 employees, and a plant area of more than 50,000 square meters. It has invested heavily in building an intelligent production line and has advanced production equipment such as laser cutting machines, laser pipe cutting machines, CNC bending machines, robot welding, laser welding, and automated spraying lines. As China Customized Sheet Metal Products Manufacturers and Customized Sheet Metal Products Factory. The company is mainly engaged in the production of outdoor furniture, office furniture (file cabinets, mobile cabinets), safes (cabinets), file compact shelving, shelves, electrical equipment and other sheet metal products.

-

40+

manufacturing experience

-

50,000㎡

Production Plant

-

200+

Employees

-

140Million+

Fixed assets

We Have Received.

As a leading manufacturer in the Yangtze River Delta Integrated Demonstration Zone (Jiashan, Zhejiang), Jiangnan Outdoor has been awarded "National High-Tech Enterprise" and "Jiaxing Green Factory" titles, with full certifications in ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 international standards.

-

Introduction to Energy Storage Cabinet Safety Energy storage cabinets play a crucial role in storing electrical energy from renewable sources or grid systems. Due to the high energy density of modern batteries, safety is a critical concern. Properly designed energy storage cabinets incorporate multi...

READ MORE -

Understanding Load-Bearing Capacity in Metal Compact Shelves The load-bearing capacity of metal compact shelves refers to the maximum weight the shelving system can safely support under normal operating conditions. This capacity is not a single fixed number but a carefully calculated value based on ...

READ MORE -

Understanding Electrical Equipment and Energy Consumption Electrical equipment, ranging from motors, transformers, and lighting systems to HVAC units and industrial drives, plays a central role in energy consumption in both commercial and industrial settings. Over time, aging equipment can become le...

READ MORE

Precision and Surface Finishing Techniques in Customized Sheet Metal Products

Beyond cutting and bending, achieving the right surface finish can determine the performance and appearance of customized sheet metal products. Surface finishing involves processes like anodizing, powder coating, electroplating, and bead blasting. Each method offers different advantages: anodizing enhances corrosion resistance for aluminum components, while powder coating creates durable, decorative surfaces for steel or stainless steel. When selecting a finish, consider the working environment, aesthetic needs, and expected lifespan of the component.

Optimizing Design for Manufacturability (DFM) in Custom Metal Fabrication

In customized sheet metal projects, design decisions directly influence production efficiency and cost. Applying DFM principles allows engineers to simplify bending, reduce welding points, and minimize material waste. For example, instead of complex multi-bend parts, consider modular structures that can be joined after forming. Additionally, maintaining consistent bend radii and allowing sufficient tolerance for laser cutting can significantly reduce rework during production.

Material Selection Beyond the Basics: Matching Alloys to Application

Selecting the right metal alloy is crucial for achieving balance between strength, weight, and cost. Beyond common steels and aluminums, advanced alloys such as 5052-H32 aluminum (for marine environments) or 304 vs. 316 stainless steels (for differing corrosion resistance) are used strategically. The following table compares some commonly used materials for custom sheet metal work:

| Material | Key Property | Typical Application |

| 304 Stainless Steel | Corrosion resistance, weldability | Food processing, enclosures |

| 5052 Aluminum | High fatigue strength, corrosion resistance | Marine panels, transportation |

| Cold Rolled Steel | Dimensional accuracy, smooth finish | Cabinets, structural parts |

Advanced Joining Methods for Custom Sheet Metal Components

Modern sheet metal fabrication utilizes a range of joining technologies that go beyond traditional welding. Mechanical fastening, adhesive bonding, and laser welding each offer specific benefits. Adhesive bonding, for example, distributes stress evenly across the joint and avoids thermal distortion. Laser welding provides precise seams with minimal post-processing. Choosing the right joining method depends on design requirements, load conditions, and the desired appearance of the final assembly.

Sustainability Practices in Custom Sheet Metal Manufacturing

Sustainability has become a growing focus in customized metal production. Recyclable metals such as aluminum and stainless steel allow for closed-loop production cycles. Moreover, nesting software helps minimize waste by optimizing material layout during laser cutting. Energy-efficient fiber lasers and CNC systems also reduce carbon emissions and electricity consumption. Manufacturers can further implement waste segregation and metal scrap recovery programs to enhance resource efficiency.

Quality Control Standards and Measurement Tools

Maintaining precision in custom sheet metal production requires strict quality assurance protocols. Beyond visual inspections, advanced measuring tools such as coordinate measuring machines (CMM), laser scanners, and digital calipers are used to verify dimensions. Consistent calibration of machinery and the implementation of ISO 9001 quality systems ensure repeatability and compliance with design specifications. Regular documentation of inspection data also helps trace production issues and optimize future runs.

Protective Packaging and Logistics for Finished Sheet Metal Products

Customized sheet metal products, particularly those with delicate coatings or polished surfaces, require special handling during transport. Packaging solutions often include foam inserts, PE films, or anti-scratch wrapping materials. For international shipping, moisture barrier bags and desiccant packets are added to prevent corrosion. Large assemblies may be secured using wooden crates or steel frames, ensuring structural integrity during long-distance transit.

Common Design Mistakes to Avoid in Sheet Metal Customization

Even experienced designers can make errors that lead to fabrication challenges or structural weaknesses. Some common pitfalls include overly tight bend radii, unaccounted material thickness during fitting, and placing holes too close to bends. To reduce such risks, engineers should follow standard sheet metal design rules, verify flat patterns before production, and consult fabricators early in the design process.

- Maintain minimum bend radius equal to material thickness for most metals.

- Avoid notches or sharp corners that concentrate stress.

- Provide sufficient clearance for assembly and fasteners.

Integrating CNC Automation in Custom Metal Fabrication

The integration of CNC automation has transformed how customized sheet metal products are made. Automated bending, punching, and laser cutting reduce manual labor while improving consistency. Smart CNC systems can read 3D CAD models directly, automatically adjusting for material thickness and bend compensation. In high-mix, low-volume production environments, automation ensures flexible yet repeatable manufacturing with shorter lead times and fewer setup errors.

English

English 中文简体

中文简体